The definition of twist of nylon line such as is as Nylon Industrial Yarn follows: the fiber structure of the line is twisted to cause relative angular displacement between the cross section of the line. The twist gives the thread a certain strength, elasticity, elongation, gloss, handle and other physical and mechanical properties, which is expressed by the number of twists per unit length. Commonly used twist-back (T.P.I) per inch or T.P.P.M.

Twisting: rotating 360 degrees around the axis is a twisting.

Twisting direction (S or Z direction) : the slanting direction of the helix formed by rotating around the axis when the yarn is vertical. The inclination of the S twist is consistent with the middle of the letter S, that is, the right hand direction or clockwise direction. The tilt of the twist is consistent with the middle of the letter Z, left hand or counterclockwise.

The relationship between twist and strength: the twist of the thread is directly proportional to the strength, but after a certain twist, the strength decreases. The twist is too large, the twist Angle increases, and the thread has poor gloss and feel. Too little twist, hairiness, loose hand. This is because the twist increases, the friction resistance between the fibers increases, which increases the strength of the thread. However, as the twist increases, the axial force of the yarn decreases, and the stress distribution of the inner and outer fibers is not uniform, resulting in the inconsistency of fiber breaking.

In conclusion, the breaking performance and strength of the thread are closely related to the twist. The twist and twist direction are determined according to the requirements of the finished product and the post-processing, generally in the direction of Z twist.

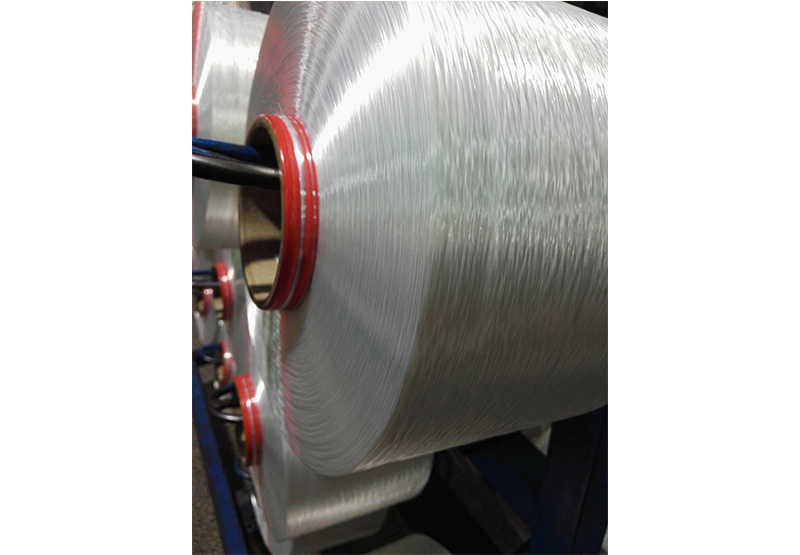

We are committed to chemical fiber and rubber reinforcing textile industry, providing high quility Industrial line such as V Belt Reinforcement