There are two ways to solve the yarn such as Dipped Chafer Fabric strength problem. One is to use more advanced spinning technology without changing the raw material to produce yarn that can be applied to easy-to-care fabrics, such as compact ring spinning technology.

The second method is to use the method of adjusting raw materials and changing the structure of the yarn. By combining the original natural fiber and fiber with good performance and meeting the requirements of easy care with certain spinning method, the yarn with ideal effect is obtained, mainly including blended yarn, composite yarn, etc., which are respectively introduced below.

1. The blended yarn

The blended spinning of two or more kinds of fibers mainly adopts the method of bulk fiber blending and strip blending. Increase the strength of the whole yarn through the raw material of the original fiber and other fibers with high strength and high modulus. This kind of composite yarn has traditional polyester/cotton, polyester/viscose, polyester/wool, etc., as well as polyester/cotton /Tencel fiber, polyester/cotton/cashmere etc.

2. Composite yarn

Two different types of fibers are interlaced with single or filament yarns, similar to a strand structure, which can be spun on a modified spinning machine or on a hollow spindle. There are mainly sailuo spinning, selofer spinning, wrapped spinning, core spinning and so on.

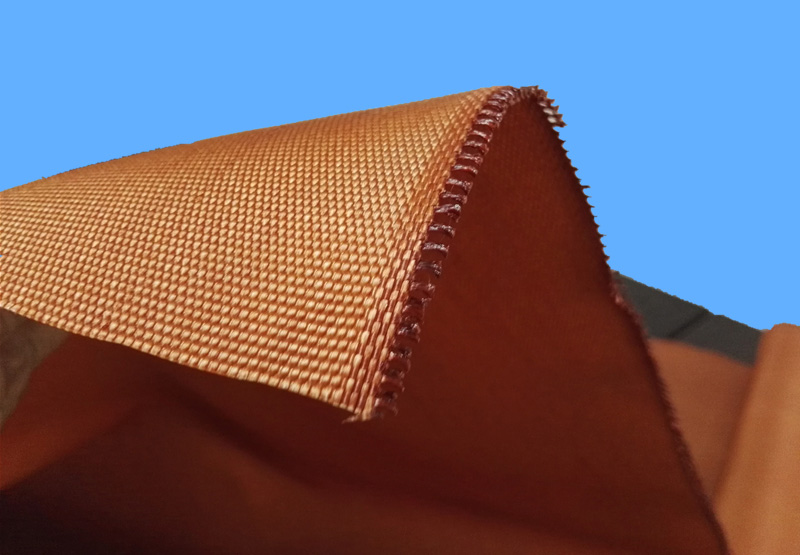

We are Dipped Belting Fabric Manufacturer. If u are interested about our products, welcome to contact us!